Today’s Electric Challenges

Plug-In Hybrid System Design, Installation, and Training all with “let’s go sailing” in mind and quality of implementation as our goal.

Solutions4 Electric Sailboat Conversions is the company that will make your seasoned sailboat into an Electric, regenerating , pleasure. We offer systems from 48V to 144V DC all with technologies that are proven, systems that make us both look good, and solutions for any budget. We can power from a 22 foot to a 60 foot catamaran.

The heart of the system is our three-phase, pulse-width-modulated (PWM) permanent-magnet motors.

They were designed specifically for marine use – to provide high-torque, direct drive at low rpm for efficient propulsion of displacement vessels. They need no transmission or reduction gear.

The motors run equally well in forward or reverse, with the same 1,000 rpm maximum speed in either direction. They can be switched from full forward to full reverse in milliseconds without harm to the motor (although for the sake of the coupling to the prop shaft, that's not recommended).

The motors are simple, rugged and made of non-corrosive materials. The rotor is the only moving part. The rotor is ringed by permanent magnets on the outer rim and is fixed solidly to a stainless steel shaft. The shaft spins in tapered roller-thrust bearings at either end. The stator windings, through which the electric current flows, are fixed in the motor's cast aluminum casing.

The only wear points are in the bearings, which are the same type as tractor-trailer wheel bearings. They have an estimated life of 150,000 hours. The bearings are double-sealed on the exterior and single-sealed on the interior to keep water out.

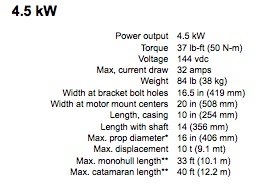

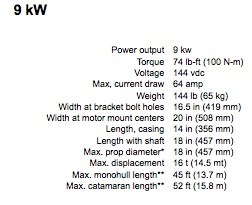

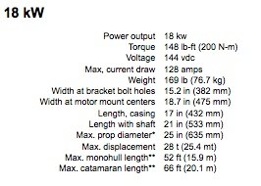

Homewood motors come in three sizes:

-

•The 4.5 kW motor is a single unit operated by a single external controller.

-

•The nine kW motor consists of two 4.5 kW motors fixed to one shaft inside a single casing. Two external controllers operate the two motors within the casing.

-

•The 18 kW motor consists of two single nine kW motors on one shaft in a single casing with two external controllers. The single nine kw motor is a new design with more compact and efficient winding. It is used only in the 18 kW motor and is not sold separately.

The motors are all approximately the same diameter but come in different lengths. There are slight variations in width between models at the horizontal ridge on the casing where the mounting brackets are bolted.

The motors are built to our design by the Homewood Group of Pittsburgh, the former manufacturing division of Westinghouse Electric. Homewood is one of the world's most experienced motor builders and service providers.

How can those little motors replace a great big diesel?

Increase the Value of Torque!

Our 18 kw motor is 17 inches long (excluding the shaft), 15 inches wide and weighs 169 pounds. Yet it can easily turn a 30 inch propeller that would choke a 50 hp diesel. How is that possible?

The answer is that our motors provide usable, prop-turning torque where it's needed most: at the low-rpm speeds at which displacement yachts motor. Homewood electric motors produce as much torque at low rpm as they do at high. They can turn as big a prop at 10 rpm as they can at 1,000.

That's why when people ask us the horsepower ratings of our motors, we tell them instead to focus on what size propeller their boat requires and the maximum rpm it needs to turn. Our motors generally take a larger prop with a greater pitch than the prop turned by a standard-equipment diesel with a much higher horsepower rating.

Horsepower is a misleading term, especially in marine engines. A diesel's horsepower rating is not a measured quantity, but a calculated one. It only applies at a specific rpm, usually around 2500-2800 for a typical marine diesel. At the low rpm used during most sailboat operations, actual diesel horsepower is much less than advertised. More importantly, diesel torque is much less as well.

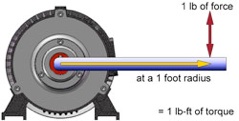

Torque is what turns the propeller, not horsepower. Torque is the twisting or rotary force applied to a shaft. It's measured as a force pushing at a fixed distance on a lever attached at right angles to the motor shaft. In the English system, force is expressed in pounds and the distance is a foot, so the torque unit is the pound-foot (not foot-pound, which is work.) In the metric system, force is in Newtons and the distance is one meter, so the torque unit is the Newton-meter.

When an engine is tested in the laboratory on a dynamometer, torque is the quantity actually measured. Horsepower is then calculated by multiplying the torque in pound-feet by the rpm and then dividing by 5,252. (For the derivation of the formula, see "Mechanical horsepower" and "Relationship with torque" in this Wikipedia article.)

Because both horsepower and torque in a diesel drop sharply at low rpm, the propeller turned by a diesel engine must be undersized. A large prop that a diesel would in theory have enough torque to turn at high rpm would stall the engine at low rpm, when the torque is much less. And of course, below a diesel's idle speed, typically from 600-1,000 rpm, torque and horsepower disappear completely because the engine stops running.

That doesn't happen with Homewood electric motors. Their torque curve is flat. Torque doesn't drop off at low rpm, and there's no minimum idle speed. An Homewood motor spins as slowly as you want it to and still turns as big a prop as it can at its maximum speed of 1,000 rpm.

Location of energy source is key difference

Why does torque drop precipitously in a diesel at low rpm and not in an Homewood electric motor? The key difference is the location of the energy source that produces the torque. In electric motors - as in steam engines - the energy source is external to the device that turns the shaft. In a diesel or any other internal combustion engine the source is internal - a series of explosions inside the engine's cylinders.

Consider an old-time piston steam engine. Water is turned into steam in a boiler and conducted by pipes to the pistons that turn the output shaft. Even if the shaft is rigidly locked in place and can't turn at all - say by a chain wrapped around a ship's propeller - the steam pressure still applies the full amount of torque to the shaft. In other words, a steam engine can have maximum torque at zero rpm.

An Homewood electric motor is essentially the same. The energy source also is external - the battery pack. Chemical reactions there produce negatively charged electrons that mutually repel each other and are attracted to the batteries' opposite, positive poles. The electrons flow from the batteries through a cable to the motor controller, just like steam flows to a turbine through a pipe.

The controller chops the direct current into pulses that flow through the motor stator windings. The pulsing current produces expanding and collapsing magnetic fields. They push against the magnetic fields from permanent magnets arrayed around the motor rotor and make it turn. As long as electricity is pulsing through the stator windings, the magnetic fields push against the rotor fields, and torque is applied to the shaft. (See Pulse-width Modulation.)

That means that the rotor - and the boat's propeller - can turn very slowly and still have the full amount of torque applied to the shaft. In fact, if the propeller were unable to turn at all - if it were locked in ice, for example - the full amount of torque could still be applied to the shaft as long as electricity is pulsing through the stator windings. Resistance on the output shaft of an electric motor - or a steam engine - does not affect the external source of energy.

That's one reason icebreakers are powered by electric motors. They can break the prop free from ice with an extra inrush of electricity. The inrush greatly increases the magnetic field strength in the motor and provides extra torque well above the normal maximum.

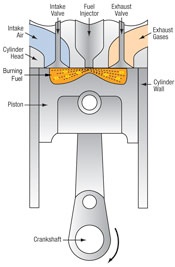

Contrast that with what happens in a marine diesel engine with its internal source of energy. Exploding fuel in the cylinders pushes on pistons that push - apply torque to - the crankshaft. Between explosions, a heavy flywheel at the end of the crankshaft keeps the speed up - and the momentum moving.

At low rpm, there are fewer explosions, a longer period of time between them and less momentum from the flywheel. [Momentum equals mv2/2, so "V" (velocity) is a much more important factor than "M" (mass) is.] If something - such as a prop that's too big - restrains the shaft from turning, the exploding fuel can't expand, the fires pushing the pistons go out and the engine stalls. Unlike the external energy source of a steam engine or an electric motor, the internal energy source of a diesel - or any internal combustion engine - is strongly affected by resistance on the output shaft.

That's why an automobile has a transmission. It lets the engine build up speed first so it can produce the torque necessary to move a car. A DC electric motor doesn't have that problem, as anyone knows who has tried to start a manual-transmission car in gear. The tiny starter motor that can be held in one hand easily lurches a 3,000 pound vehicle forward as soon as it begins turning. Even if the car is in third gear, the starter motor can move it. But try to move the car in third gear with its 300 hp internal combustion engine. As soon as the clutch is let out, it stalls.

That's also the reason modern diesel locomotives are actually diesel-electric. A steam locomotive has no trouble powering its drive wheels directly to set a 100-car coal train in motion from a full stop. Its energy source, the fire in the boiler, is external and unaffected by the load on the drive pistons.

But the diesel locomotive's energy source is combustion inside the cylinders, which couldn't take place if the engine were directly connected to the drive wheels. Even multiple 3,200 hp locomotive diesel engines connected directly to the drive wheels would never be able to move the train. Unless it is first running at a high enough rpm, the huge diesel engine in a locomotive can't produce the necessary torque. The multi-gear transmission required for such a massive load would be impossibly large.

So a diesel locomotive transmits torque to the drive wheels through electric motors. The diesel engine spins an alternator to produce electricity for the motors, and they turn the wheels. Unlike the locomotive's diesel engine, the electric motors can apply full torque to the wheels even when they're held at zero rpm by 10,000 tons of coal.

And unlike a marine diesel, an Homewood Hybrids motor can apply full torque to the shaft at zero rpm even when it's being resisted by a large, three-bladed propeller.

Standard torque unit

The real Old Navy, 1919. Humping coal in the USS Troy's boiler room.

Pair of steam engines totaling 21,000 hp for the USS Milwaukee, 1904. Cylinders with pistons at top, crankshafts at bottom.

Icebreakers use electric propulsion to help break props free from ice. US Coast Guard icebreaker (L) with Military Sealift Command tanker refueling McMurdo Research Station in Antarctica. Background: US research ship (L), Russian icebreaker (R).

Inside a diesel cylinder

A steam locomotive's energy source - the boiler - is completely separate from the cylinders and pistons that drive it.

On an average if a sailboat powered by diesels motored for 24 hours without wind the comparison sailboat that had electric propulsion would use approximately 10 hours of fuel all depending on the battery pack size.

The goal is conversion: getting the old, end of life diesels, off the waterways. In some situations we install a very efficient DC diesel genset that runs only when batteries need charging, or your motors need to run without the ability to sail. In this website you can discover different systems with the unique philosophy of installation with Solutions4Hybrids.

Solutions4Hybrids DBA, Solutions4US, Inc. 5409 Overseas Highway #312, Marathon, FL 33050

888.976.5884 • 305.619.0201 • FAX 888.785.5684